We exceeded our 50% sustainable paper packaging goal | Takeda Stories

How we exceeded our goal of 50% sustainable paper packaging by 2 years

Learn about three ways we’re innovating to reduce our paper usage and ensure the paper we use comes from sustainable sources.

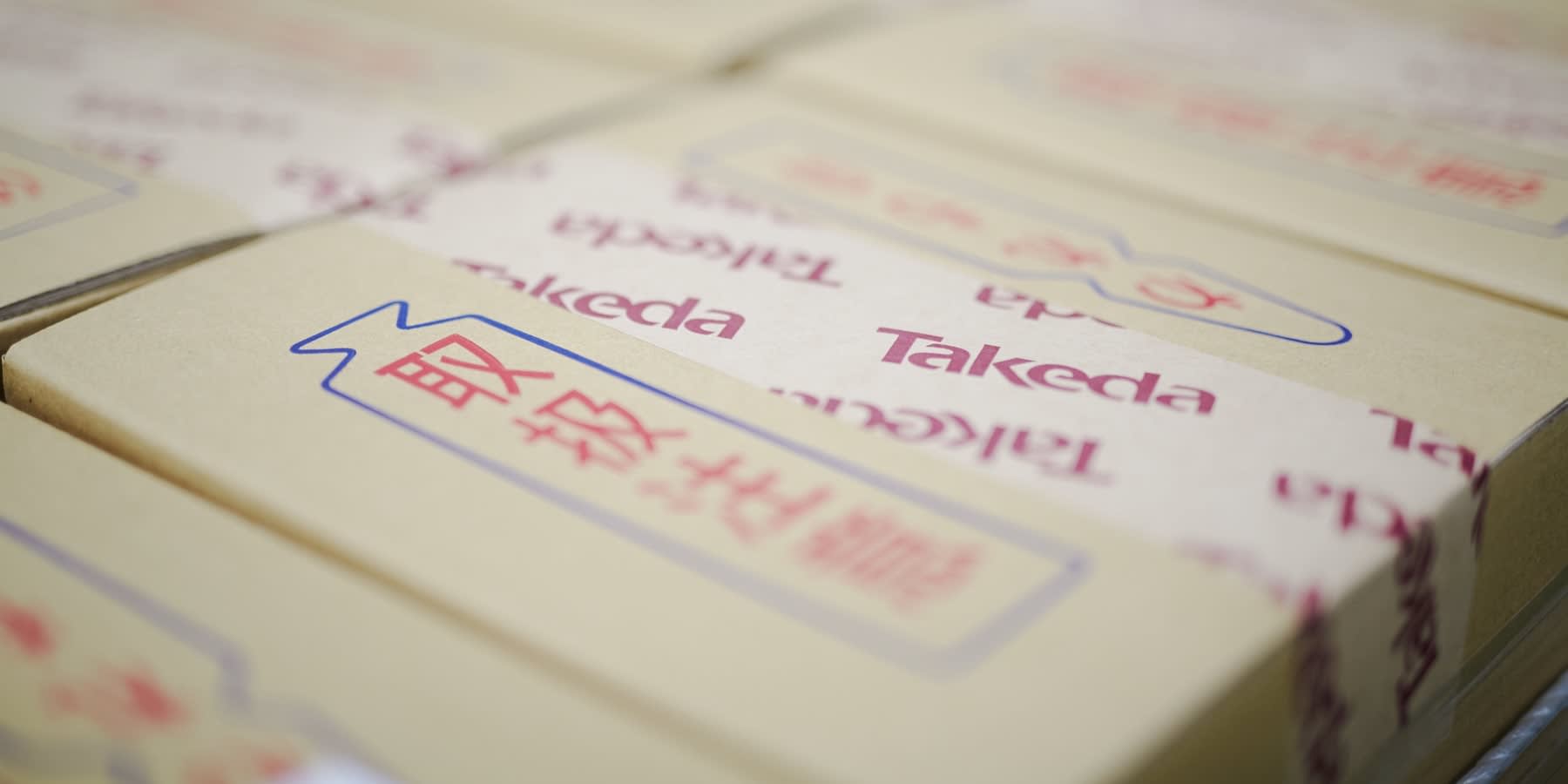

What does paper have to do with creating better health for people and a brighter future for the world? Quite a lot, actually. Paperboard boxes hold each of the 500 million units of medicine we produce every year. We include paper leaflets with important product information in nearly every box. And larger paperboard boxes ship these units around the world. In all, we use up to 10,000 tons of paper per year.

Paper may be essential to carrying out our centuries-old mission. But taking innovative approaches to reduce our paper usage and ensure the paper we use is sustainably sourced is key to keeping our commitments to people, patients and the planet for years to come. We measure our progress in creating long-term value over time through our Corporate Philosophy metrics. And we’re making incredible progress. In 2023, we exceeded — by 3% and two years — our Corporate Philosophy metric to have 50% sustainably sourced paper packaging by 2025. Meanwhile, we are continuing to build on our efforts and identifying further opportunities for sustainable packaging across existing and new products.

This is an enormously complex undertaking that reaches across our entire supply chain.

Luciana Pellegrino, president, World Packaging Organisation

President of the World Packaging Organisation Luciana Pellegrino says she recognizes our company’s bold investments, and how we pursued multiple pathways for improvement at the same time.

“What stands out is the variety of technological advancements taking place simultaneously. From raw material source, to printing technology and digitalization, these efforts create a holistic approach for greater efficiency and sustainability throughout the packaging and product life cycle.”

Here are three of our innovative efforts to make paper packaging more sustainable.

1. Partnering with our suppliers for more sustainable packaging

Jörg Michaelis, design-to-value lead, Direct Procurement, Takeda

For paper packaging to be considered sustainable, it needs to be either made from recycled paperboard or certified as such by an organization like the Forest Stewardship Council (FSC). Jörg Michaelis, design-to-value lead on the Direct Procurement team at Takeda, says we’ve been asking our 50 suppliers of paper-based packaging material around the world to obtain the certification. This isn’t always easy, since the process can be costly and time-consuming. But Jörg and his team stress that the certification doesn’t just benefit our company.

“We tell our suppliers that if we can make our sourcing more sustainable, we can do a lot for the planet,” he says. “We also stress that suppliers can advertise their certification, which benefits them and the industry as a whole.”

Kerstin Löffler, vice president of Marketing, Communications, and Environmental, Social and Governance (ESG), Faller Packaging

One of those suppliers is Kerstin Löffler, vice president of Marketing, Communications, and Environmental, Social and Governance (ESG) at Faller Packaging. She says she has been impressed by Takeda’s interest in her company’s value chain, which she saw firsthand when she presented on Faller’s ESG approach to representatives from our company in 2023.

“They wanted to see the whole picture,” she says. “We are Takeda’s scope 3, meaning our products and our corporate carbon footprint factor into Takeda’s total emissions. So the more sustainable we get, the more of a positive impact it has on Takeda. Takeda’s understanding of that and desire to push us to be even more sustainable stands out in the industry.”

In addition to using FSC-certified paper, we’re working toward using recycled paper in our paper packaging.

“E-leaflets allow patients to use technology to optimize the way they access important information about their medicines. And if we can remove the paper leaflets that we include in each of the 500 million units of product we produce each year, we could save a lot of paper, as well as natural resources.”

Michael Ritter, head of Serialization and Digital Enabling, GMS

2. From paper to digital product information leaflets

Michael Ritter, head of Serialization and Digital Enabling, GMS

In his role within our Global Manufacturing & Supply organization, Michael Ritter says health authorities are showing interest in adopting digital, or e-leaflets, which could eventually replace paper versions. In addition to greatly reducing our paper usage, Michael says this transition also stands to enhance the patient experience.

“E-leaflets allow patients to use technology to optimize the way they access important information about their medicines,” he says. “And if we can remove the paper leaflets that we include in each of the 500 million units of product we produce each year, we could save a lot of paper, as well as natural resources.”

But product information leaflets are highly regulated, and some countries have been quicker to go paperless than others. In many countries in Europe and Asia, we're still in the pilot stage.

Even so, we’re committed to the process. E-leaflets allow our company to quickly and easily update product information as needed, and they allow patients to zoom in on the text, making the notoriously miniscule type easier to read.

3. A move toward more energy-efficient printing

Secondary packaging — the box that holds the blister pack or bottle containing the medicine itself — is prime real estate for product branding and information. This requires that we print imagery and text directly onto the box.

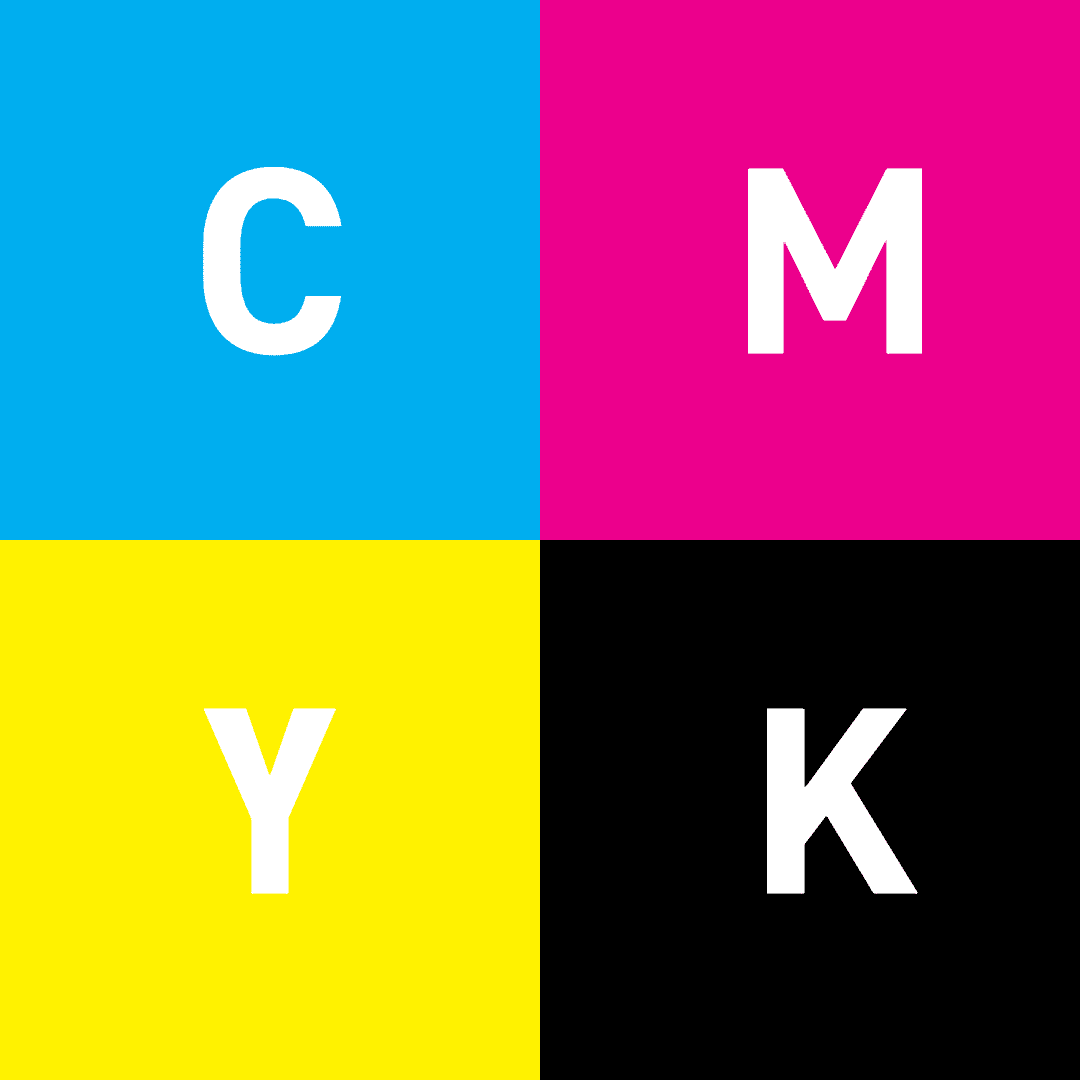

One of the easiest ways to reduce the environmental impact of our printed materials is by reducing the number of ink colors we use. We’re replacing Pantone colors — which are popular in graphic design because of their vibrancy and wide-ranging color options — with a different color model. Cyan, Magenta, Yellow, and Key (black), or CMYK, allows us to create the same visual experience for the patient or medical practitioner using fewer ink colors.

John Ford, head of global artwork governance, Takeda

John Ford, head of global artwork governance at Takeda, says he works with his brand colleagues to ensure our agencies and printers use CMYK when they design artwork for our products.

“With Pantone, if we change a color, we need to clean the printing station,” he says. “When working with CMYK, you don’t need to change the printing stations, which brings an environmental benefit. Naturally this also saves money; it's faster, leaner and less costly; and there’s an energy reduction.”

As we continue with these efforts, we are confident in our ability to continually increase our percentage of more sustainable paper packaging. In addition, we’re exploring other innovative ways to substitute plastic with paper where possible. For example, by replacing plastic-based tamper-evident seals with fiber-based seals, we can make a package that’s entirely paper-based and easier to recycle.

Sriman Banerjee, executive director and head, Diagnostics, Software Devices & Packaging Development, Takeda

Sriman Banerjee, executive director and head, Diagnostics, Software Devices & Packaging Development at Takeda, says we’re following the principles of sustainability by design and the circular economy — production models that aim to reduce waste — to guide our development going forward.

“Takeda has global partnerships with several packaging industry consortiums and partners to share open-sourced knowledge towards sustainability development,” he says.

Share this story