Protecting our planet: Water

Protecting our planet: Water

Data and Digital Technology Helps Conserve Over 2 Million Liters of Freshwater at Manufacturing Plant in Osaka

Our manufacturing site in Osaka, Japan, has achieved significant success in freshwater conservation through innovative data-driven initiatives, with collaboration between the production, engineering and data science teams resulting in significant reductions in water usage.

The manufacturing process requires large amounts of purified and sterile water, particularly for drug production and facility cleaning. With growing product demand, shortages of distilled water can pose operational challenges and potentially lead to production delays. When plans to build a new distilled water facility to address this issue proved too water intensive and costly, the teams sought an alternative approach.

Using Takeda’s real-time data collection infrastructure, they embarked on a data-driven journey to assess and optimize distilled water usage. The system’s real-time visualization and analysis allowed them to identify usage patterns and pinpoint areas of excessive consumption. At the same time, sensors were installed to monitor manually operated equipment, providing a comprehensive picture of usage and enabling targeted improvements.

Through comprehensive analysis and strategic adjustments, the teams successfully reduced distilled water consumption by over 450,000 liters annually. It also helped to reduce overall freshwater withdrawal by two million liters annually which also led to significant savings in city gas usage. Notably, these efforts resolved a critical production challenge and underscored the site's commitment to environmental stewardship and contribution to Takeda’s goal to reduce our freshwater withdrawal by 5% by 2025 from a FY2019 baseline.

The success of this initiative demonstrates the transformative potential of data-driven decision-making in overcoming operational challenges and minimizing our environmental impact. Moving forward, the site will continue to harness the power of data science to drive sustainable manufacturing practices and foster a culture of innovation and environmental responsibility.

Belgian manufacturing site leads the way in water recycling

Making a commitment to conserve water is one thing. Turning that commitment into a reality is quite another. And it can be challenging –our team in Belgium pioneered the recycling of rainwater and wastewater at our Lessines manufacturing site.

We’ve teamed up with the Belgian enterprise Ekopak, which developed an innovative technology. By re-using rainwater and treating our wastewater, the manufacturing site is currently reducing its freshwater withdrawal by 50%, aiming for a 90% reduction by 2027. That's the equivalent of 1 million liters of freshwater per day and to put this figure into perspective, it’s equivalent to the annual water use of nearly 10,000 Belgian citizens, which just happens to be the size of the population in the city of Lessines.

This is the first large-scale wastewater recycling facility of its kind to be used in the pharmaceutical industry in Belgium. Investment in the facility, which also reduces the use of chemicals such as acid and caustic soda in water treatment, is part of a much wider strategy to sustain and protect natural resources at Lessines. The site already uses 100% renewable electricity. It also has a cogeneration plant that generates electricity using a natural gas-powered turbine. And we installed more than 8,000 photovoltaic panels until today and plan to install more in the coming years. By 2026, the site aims to produce 80% of the needed electricity through e.g., the installation of geothermal wells and two wind turbines. The plant systematically monitors its energy efficiency and has deployed a biodiversity management program.

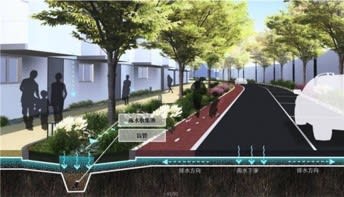

A sponge city harvesting rainwater

At our Tianjin plant in China, we followed a “sponge city design” to recover rainwater. We created a subsidized greenbelt and permeable roads that are used to absorb and collect rainwater. The streets have an underground water collecting system, which helps to reduce freshwater withdrawal.